Pad Technology

Pad Technology Basics

Tool-specific Technology

Material Choice & Aggression

Pad Shape & Design

Special Features

About Pad Aggression

“Aggression” is a measure of the strength of abrasion a pad performs on a clear coat. You might hear other manufacturers call this a pad’s “correction” or “cut.” The most aggressive pads adeptly remove deep defects but may require an additional step of refinement or polishing. Less aggressive pads won’t be as efficient or effective with defects but can leave a surface polished, smooth and haze-free. Generally, you’ll move from a more aggressive pad to a less aggressive pad as you progress through a project.

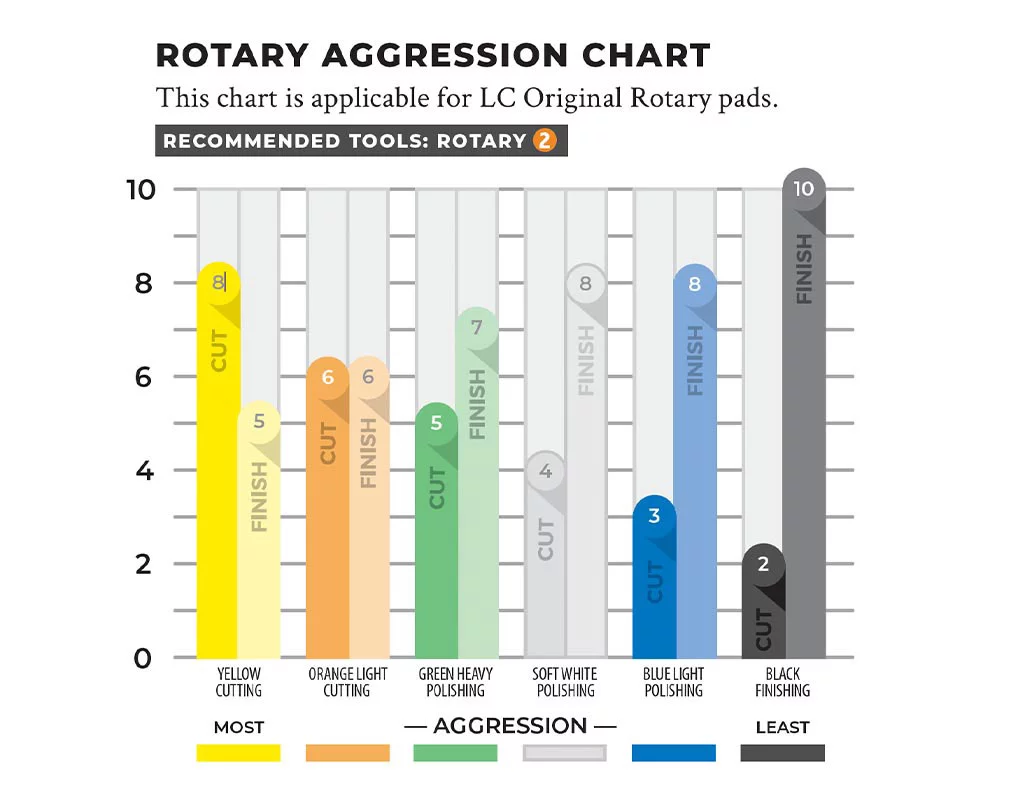

To illustrate, here’s a sample aggression chart for one of our pad lines. Each product’s aggression chart uses two sets of numerical ratings.

- Cutting, rated from 1-10, indicates a pad’s ability to remove defects. The higher the number, the deeper the pad material cuts.

- Finishing, rated from 1-10, indicates a pad’s ability to refine surfaces. The higher the number, the more refined finish the pad material leaves.

The cutting and finishing ratings have an inverse relationship, which means that products with a high cut rating will have a low finish rating (and vice versa). Products like our purple foamed wool that have cut and finish numbers that are very similar are closer to a “one-step” pad.

Download our Master Aggression Chart below to get a visual overview of our pad collections, rated in aggression levels.

Pad Styles & Features

LC pads are designed to solve your most pressing problems. Longevity. Consistency. Performance. Efficiency. Each design undergoes more than 200 hours of lab and field testing, evaluating everything from airflow to tear resistance, to ensure that it will meet your needs. Our different pad styles each have their own features. That way, there’s a pad for every tool and every project. Click through our pad lines below to compare design features.

The nature of open-cell pads means that they absorb some of the compound or polish, trapping it beneath the working surface of the pad where it can no longer contribute. CCS Technology™ solves this common problem using strategic patterns of partially closed foam cells. Independent columns evenly disperse polish from the CCS pockets onto the working surface.

The nature of open-cell pads means that they absorb some of the compound or polish, trapping it beneath the working surface of the pad where it can no longer contribute. CCS Technology™ solves this common problem using strategic patterns of partially closed foam cells. Independent columns evenly disperse polish from the CCS pockets onto the working surface.

- Slow absorption rate: Extends polish performance by reducing absorption

- Improved operator control: CCS pockets gradually release polish as needed

- Prevents pad skipping: Pockets reduce surface friction, allowing operator to run pad flat on a working surface

- Creates less heat: CCS pockets reduce surface contact, resulting in less friction-generated heat

Developed to maximize the potential of long throw orbital polishers, our Heavy Duty Orbital (HDO) pads utilize the popular cutting, polishing and finishing foams found on our SDO line. A dual layer construction – using a high-density foam sandwich layer – means HDO pads transfer more of the action from your polisher to the pad face itself.

Developed to maximize the potential of long throw orbital polishers, our Heavy Duty Orbital (HDO) pads utilize the popular cutting, polishing and finishing foams found on our SDO line. A dual layer construction – using a high-density foam sandwich layer – means HDO pads transfer more of the action from your polisher to the pad face itself.

- Enhanced performance: Maximized cutting and polishing action when paired with 15mm or 21mm orbital polishers

- Modern tapered design: Even compression and precision polishing

- Increased durability: Build to withstand heavy duty operation without overheating

Waffle foam pads are built to maximize performance, minimize heat and reduce present pad skipping. The wavy waffle texture allows airflow underneath the pad to release heat. Operator control is improved by the features of our convoluted design.

Waffle foam pads are built to maximize performance, minimize heat and reduce present pad skipping. The wavy waffle texture allows airflow underneath the pad to release heat. Operator control is improved by the features of our convoluted design.

- Improved operator control: Waffle design improves control and user experience

- Prevents pad skipping: Convoluted foam reduces surface friction, allowing operator to run pad flat and glide over the working surface while polishing

- Creates less heat: Reduced surface contact creates less friction-generated heat while buffing

These pads are manufactured using the finest engineered foams that are specifically designed for compounding, polishing, finishing and waxing the newer, harder, scratch-resistant finishes. They are thermally reticulated with an open cell structure, which allows air to circulate through the pad, reducing heat buildup.

These pads are manufactured using the finest engineered foams that are specifically designed for compounding, polishing, finishing and waxing the newer, harder, scratch-resistant finishes. They are thermally reticulated with an open cell structure, which allows air to circulate through the pad, reducing heat buildup.

- Better edge: Beveled edge allows access under mirrors, door handles, trim and more

- Recessed back: Precision alignment provides balance and eliminates the possibility of contact with a backing plate

- Machine washable: Safely clean pads without affecting performance and durability

Using specific blends of microfiber and special bonding materials, we created unique microfiber pads to have durability and longevity that is tough to compete with. Our microfiber pad line offers its own unique blend of microfiber threads, paired with the appropriate foam interface to suit finishing, cutting or small polishing needs.

Using specific blends of microfiber and special bonding materials, we created unique microfiber pads to have durability and longevity that is tough to compete with. Our microfiber pad line offers its own unique blend of microfiber threads, paired with the appropriate foam interface to suit finishing, cutting or small polishing needs.

- Accurate and precise: Precision tapered profile (HDO Microfiber) is ideal for tight areas

- Robust hybrid foams: Dense European foams allow for wide range of aggression

- Exact fit backing: Get the perfect fit every time with an easy-to-center loop

One of the first pads ever offered by Lake Country, our premium knitted wool pads are known around the world. Like natural sheepskin pads, these pads have an increased cutting ability, but offer more consistent performance from pad to pad. Along with coming in a greater variety of sizes, these pads also lint much less than a traditional tufted wool pad.

One of the first pads ever offered by Lake Country, our premium knitted wool pads are known around the world. Like natural sheepskin pads, these pads have an increased cutting ability, but offer more consistent performance from pad to pad. Along with coming in a greater variety of sizes, these pads also lint much less than a traditional tufted wool pad.

- Durable backing: More durable than natural backing material, which allows for more washings

- Premium blends: Signature wool blends for fast, effective cutting with great finishing qualities

- Reduced linting: Knitted pads lint less, making your shop or work area cleaner

Tufted wool is a traditional, aggressive cutting material that’s been used across the industry for decades, making it one of the overall best-selling pad materials. Lake Country is the only manufacturer to offer both steamed and unsteamed wool pads to fit any need or purpose.

Tufted wool is a traditional, aggressive cutting material that’s been used across the industry for decades, making it one of the overall best-selling pad materials. Lake Country is the only manufacturer to offer both steamed and unsteamed wool pads to fit any need or purpose.

- Quick cutting: Engineered wool and other yarns are the fastest cutting products

- Durable and strong: Signature backing construction and material blends offer a pad with extended durability

- Curved edge: Allows for perfect pad alignment while protecting the working surface

LC Innovation

Learning & Resources

Introducing Lake Country’s New MarineLine Buffing Pads

Experience Superior Marine Detailing with Our Specialized Range At Lake Country, we’re excited to unveil our all-new MarineLine—a comprehensive collection

Why Would I Need an HDO Pad?

Written for the IDA Detail Dialogue, Published December 2022 In detailing, we naturally obsess over tiny details – hence the

The Most Important Thing To Polish?

Polishing glass ranks as one of the most overlooked detailing skills and services. Aside from being aesthetically pleasing to have

"*" indicates required fields