Introducing Lake Country’s New MarineLine Buffing Pads

Experience Superior Marine Detailing with Our Specialized Range At Lake Country, we’re excited to unveil our all-new MarineLine—a comprehensive collection of buffing pads specifically engineered

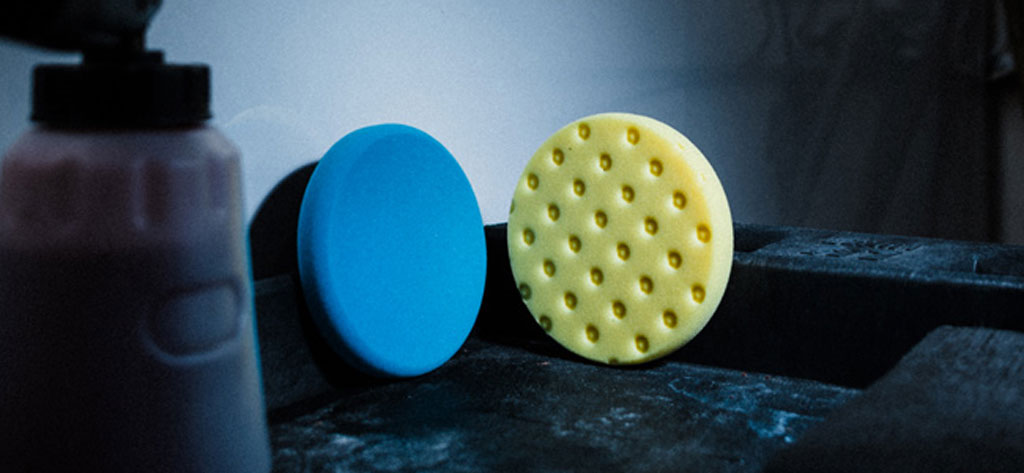

“Can you use a DA pad on a rotary?” and “can you use a rotary pad on a DA?” are two extremely common questions that we get asked all the time. These colorful foam discs look pretty similar to the uninitiated, and it’s not like the foam we use has a personal preference!

Yet while it is true that basic foam pad designs work pretty well on both Dual-Action (DA) and rotary machines, that does not mean we can’t create superior pads, with characteristics specialized for each application individually and together.

The battle between rotary and Dual-Action (DA) machines is one that detailers take staunch sides on. Whatever your opinion, when buffing or polishing, every technician critically selects the tool that works best for the project in front of them. While every detailer gets creative in their own way, it is important to note that rotary and DA machines work very differently from one another, with the physics of each placing different demands on the pads.

For example, the outer edge of a rotary polisher travels much faster than its center, a reason why we design pads with curved edges and a recessed backing for rotary. Conversely, when using a DA machine, the whole pad face oscillates and orbits in unison. Therefore, in order to create the best polishing pads on the market, we must take into consideration the diversity of weight, balance, rigidity, density and cooling in all different applications.

The Precision Rotary Line combines our LC original foams (with CCS technology) with an updated shape/profile to maximize performance, durability and accuracy when polishing with a rotary machine. The CCS pockets generate less heat and prevent pad skipping during use in rotary applications.

Our Heavy Duty Orbital (HDO) foam pads are a great example of innovative thinking for use on a DA machine. Built with a dual layer construction and a firmer foam base, this technology provides all the benefits of a tapered pad, such as backing plate protection and even compression, while decreasing the quantity of foam on top to increase power and reduce pad motion. The result is the user having more control and increased efficiency, but the benefits are far less apparent when used on a rotary.

On the flip side, you’re not going to get the best result when using a thick wool pad on a DA machine. On a rotary machine, the compound or polish pairs well with the rotational action, carried along the fibers at a level necessary to accomplish the task. On a DA machine, the fibers are made to wiggle around loosely, which reduces their effectiveness.

If you are looking for extra cutting ability on a DA machine, Lake Country now offers microfiber pad designs which retain a thin foam backing for comfort and control while bonding it to a tightly packed microfiber surface. Because the fibers are short, they are well suited for an orbital action and offer an enormous combined surface area for maximum cutting efficiency.

To learn more about foam pads, rotary polishing, DA polishing and the similarities and differences between the two, follow us on social media and be sure to reach out to us for advice!

Experience Superior Marine Detailing with Our Specialized Range At Lake Country, we’re excited to unveil our all-new MarineLine—a comprehensive collection of buffing pads specifically engineered

Written for the IDA Detail Dialogue, Published December 2022 In detailing, we naturally obsess over tiny details – hence the name, I suppose. A smudge,

Polishing glass ranks as one of the most overlooked detailing skills and services. Aside from being aesthetically pleasing to have pure transparent glass, it’s incredibly

Experience Superior Marine Detailing with Our Specialized Range At Lake Country, we’re excited to unveil our all-new MarineLine—a comprehensive collection of buffing pads specifically engineered

Written for the IDA Detail Dialogue, Published December 2022 In detailing, we naturally obsess over tiny details – hence the name, I suppose. A smudge,