Introducing Lake Country’s New MarineLine Buffing Pads

Experience Superior Marine Detailing with Our Specialized Range At Lake Country, we’re excited to unveil our all-new MarineLine—a comprehensive collection of buffing pads specifically engineered

Polishing glass ranks as one of the most overlooked detailing skills and services. Aside from being aesthetically pleasing to have pure transparent glass, it’s incredibly important–literally a matter of life and death–to see the road ahead properly. With the low sun, rain, snow and grime of winter upon us (sorry Southern hemisphere), I think now is a great time to talk about how and why machine polishing glass is so important.

Cleaning glass with a liquid cleaner typically removes surface dirt, but do you notice if you then wipe over the ‘clean’ glass with a damp cloth, you can still see streaky impressions left behind? These leftover stains are fallout, acid rain, and chemical residues on the surface—highly resistant to most glass cleaner sprays, and a stained surface will also tend to get dirtier and more stained more quickly. It’s much easier to maintain a clean surface than having to keep restoring it. Fortunately, one of the easiest ways to fully remove glass staining is by simple machine polishing.

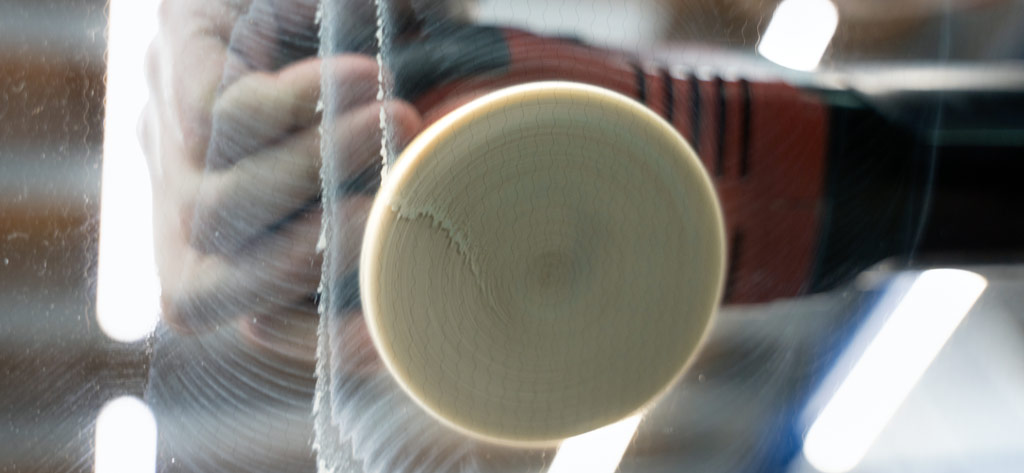

In our workshop we keep old microfiber pads for this purpose, helping to extend their useful life. Take your orbital polisher and pad, apply a medium cutting compound, and polish the glass in sections. I normally divide a windshield into quarters, and for my convenience I tend to put individual squirts of compound on the glass in those sections before I get started – it just saves me time as I don’t have to keep stop-starting.

Don’t be afraid to apply some pressure – you will clean the glass faster, and it won’t cause any damage. It also won’t do anything at all to remove any surface scratches from the glass. All you’re doing is cleaning it ultra-efficiently, and those streaky stains will be gone in no time!

A beautifully detailed paint job will be thoroughly let down by a scratched windshield. While the paint pops, under many light conditions, the arcing scratches caused by gritty wiper blades (don’t forget to clean/replace these afterward) become an even bigger distraction – not to mention a potential safety issue in the worst cases, as they can increase glare.

Machine polishing glass with a microfiber pad will not remove these scratches. However, with a Lake Country rayon glass polishing pad and a special compound, you can!

This is a technically trickier skill, but anyone with a moderate amount of experience should be able to master it quickly. For faint scratches, a random orbital polisher and a 5” rayon pad will do the trick (deeper scratches may require a rotary and a 3” rayon pad instead for extra, more targeted cut). Glass polishing pads are a different material and work differently to the polishing pads used on paintwork, and when combined with a cerium oxide solution they are aggressive enough to remove scratches in the glass itself, returning a pure optical clarity to the glass. Cerium oxide can be bought as a pre-mixed solution, or you can buy it in powder form and mix it with water yourself; a thin, watery mixture is usually strong enough – start from there, increasing the cerium oxide content if necessary.

Once you’ve finished polishing, be sure to wipe away the compound residue fully, and then use I.P.A. with a different microfiber cloth to guarantee a pure surface. If planning to apply a glass coating, I would also recommend cleaning the glass with a panel wipe before the I.P.A. to ensure zero oils are left that could inhibit the coating’s bonding abilities.

For more on this topic, and quite an extreme example, check out this YouTube video featuring Kelly Harris and some unusual scratches on a Porsche window…

Until next time,

Jay @ LC

IG: /jaybroomdetailing

FB: /jay.broom.detailing

FB group: Detailing with Lake Country

Experience Superior Marine Detailing with Our Specialized Range At Lake Country, we’re excited to unveil our all-new MarineLine—a comprehensive collection of buffing pads specifically engineered

Written for the IDA Detail Dialogue, Published December 2022 In detailing, we naturally obsess over tiny details – hence the name, I suppose. A smudge,

I don’t really talk much about it these days but my experience working with / around cars goes back a looooooong way, and actually included

Experience Superior Marine Detailing with Our Specialized Range At Lake Country, we’re excited to unveil our all-new MarineLine—a comprehensive collection of buffing pads specifically engineered

Written for the IDA Detail Dialogue, Published December 2022 In detailing, we naturally obsess over tiny details – hence the name, I suppose. A smudge,